A Roller Bearing Run In Stand For Testing Motor Controllers

We started out with nothing but a piece of foam to lay the locomotive on to test our motor controllers, and on its side no less! Alligator clip test leads clipped on to any convenient lcoation to supply power. It's awkward to say the least. Besides an accident waiting to happen, it's nearly impossible to test steam engines short of upside down. That got old quick!

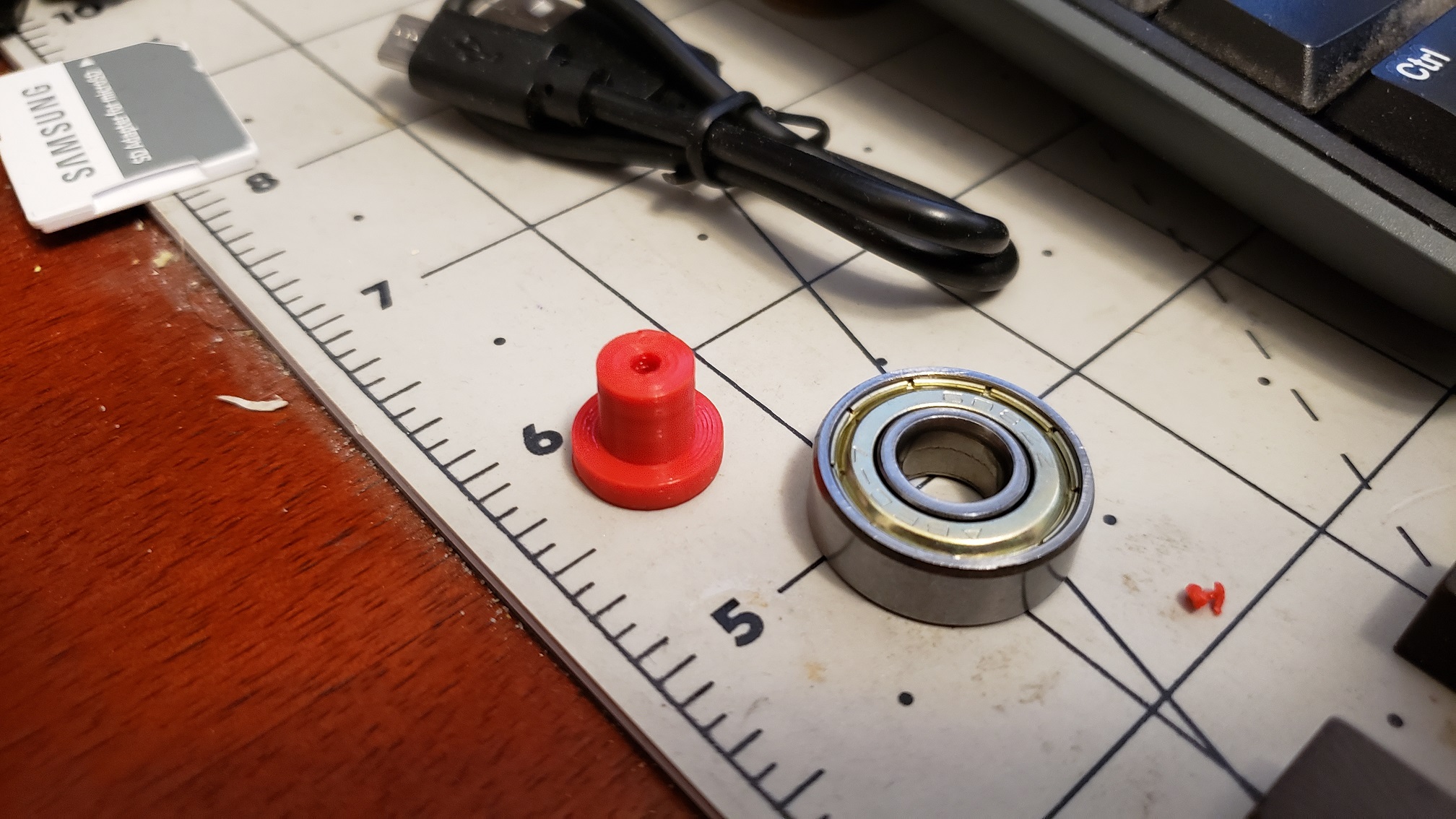

Looking at the ubiquitous (read inexpensive) roller skate bearings and a few quick measurements later produces a design, and once sliced and printed, a hub to test fit for the inner race. The outer race is the actual running surface the drive wheels engage. It takes a few tries to match the inner race opening, but that's the nature of the beast. I've quickly learned that although the model dimensions are correct, it doesn't guarantee the 3D printed plastic is within spec...

Next step is to fashion a set of support assembly halves to align a set of roller skate bearings at the correct spacing. That takes more than a few tries since the initial design requires modifications to work the way I want it to. What I thought was the final design clamps over the Piko flex track rails and tie strips just fine, but fails miserably on Aristocraft track. A few final tweaks yield a design flexible enough to fit both styles of track.

The only deficiency with the original is how to feed power to the "device under test". Running power through the bearings will damage them. And while those alligator clip test leads work, it's a royal pain in the butt trying to get around the back side of any arangement. The USA Trains style shoe pickups on the diesels I'm testing are an easy enough to target, but all bets are off trying to keep them connected with the locomotive rocking back and forth on them.

A two piece clamshell design that uses copper tape to conduct the power up from the rails directly to the pickup shoes fits the bill. It also fits nicely between the wheel supports. The copper tape has a "peel and stick" backing, and I have plenty of it. The fit doesn't have to be precise either. It just has to make contact with the rails and provide continuity to the power pickup shoes.

This allows any locomotive with pickup shoes to be supported on a section of track of suitable length and powered by it, as if it were sitting directly on the track. The task of attaching those alligator clips just got a whole lot easier too! Of course, any means at hand that allows power to be fed to the track is now available to us and at our disposal.

Another benefit of the design is the ability of the wheel support assemblies to "self center". If the locomotive driver isn't exactly positioned between the two roller bearings, it rides higher than it should, and the weight of the locomotive provides a net force that pushes the assembly toward the driver's center. Once centered, the assemblies can be clamped tightly in place if desired, but I just leave them "free to float" to easily change between locomotives.

The cost motivation is obvious. Ease of use is right up there too. Ease of assembly is not quite as charming, but doable, with a minimum of tools required. I bought a pack of 100 (608-2RS) bearings for $20, shipped to my door. That's 20¢ a piece! A four axle diesel requires four bearings per axle, for a grand total of sixteen. That's only $3.20!

The copper foil tape assortment was $22 for a three roll assortment. Each roll is 66 feet long. Each power "pod" requires about a 2" length of the 1" wide tape, or about 2¢ of copper. Negligible. The M2.5 socket head screw assortment kit I used to assemble them is around $12 for 20 sets of each length. Each axle requires 6 screws and nuts, 2 more sets for the power pods, for a total of 26 sets.

That will exhaust most assortment kits before completion, so figure on buying two kits, or just buy in bulk only the size needed. I chose stainless steel for the corrosion resistance, but it isn't necessary since it will only be used on the bench indoors. The hardware in bulk is around $13 for sets of 100, or 13¢ per set, for a total of $3.38. Add in the cost of 3D print filament and it's still well below $10 for a 4 axle run in stand!

We invite you to enjoy this video our motor controller and run in stand in operation if you're so inclined. It highlights the fusion of a number of gadgets and projects we can't possibly fit on a web page. Even our Barkyard Blog posts can't capture all the details the videos can.