A Bigger Battery Box for Passenger Car Lighting Controllers

We started out with nothing but a Bachmann ten wheeler and a couple of passenger cars. I always enjoy having the lights in the passenger cars, but there are only the two incandescent bulbs, powered by a 9V battery. I may have kept a few of those batteries on hand for my transistor radio in the distant past, but those days are long gone. Talk about old school! I wanted something that not only lasted longer than the few hour lifetime of 9V batteries, but also much more brightness than two bulbs provide.

We found nothing available to replace the "archaic" 9V system with modern technology. A rechargeable 9V battery comes in around $20, an expensive proposition just to avoid having to throw away batteries that last maybe a few operating sessions. Even so, the short running time between charges is not an improvement, not to mention it would do nothing to solve the brightness issue.

The prototype LED strip lighting used 5050 LED strips which require a 12V supply and a driver to operate them. After a number of failed attempts to shoehorn those electronics into that single box along with everything else, it was apparent they would need to go elsewhere. It's one thing to have everything working laid out on the workbench, but quite another to pack it all into the limited space in the passenger cars.

A couple of iterations later, we have a 3D printed battery box that will snap in place of the original, and only slightly larger in each dimension. We fitted some passenger cars with the prototype electronics and ran them around the Barkyard to put them to the test. They did well enough, even with the subdued brightness levels we had to use due to limitations of the boost converter we used for the supply voltages.

It uses an Arduino based WiFi capable microcontroller, so no need for a dedicated remote control, like those we're always losing between the seat cushions. It acts as a miniature web server, serving up the user interface to any browser. Any web browser capable device can control it, like the smart cell phone most of us already have in our pocket. Or a tablet. Or a laptop. Even a desktop computer. Any browser enabled device.

Our entire controller, including the battery, is around $20. Sound interesting? We thought so... So much so, that we've built many different types of controllers around this same core technology. In addition to these lighting controllers, we have a number of motor controllers based on the same Arduino device. The idea is to simply change out the user interface and configuration files based on the application. Simply add the necessary libraries to support the hardware and we're done.

After a few accidents, what we'll call "dragging equipment" failures, it was obvious the battery box design was the limiting factor. Back to the drawing board! The "first generation" design relied on a "sliding fit" between the lid and the box itself. The lid snapped into the bottom of the passenger car in place original 9V version. Then grooves in the box were supposed to slide over the appropriately shaped edges of the lid. Works great off the car, not so much once the lid is snapped on...

Unfortunately it neglected the fact that once the Arduino is mounted to the cover, it's impossible to slide the box over it. While the box would "snap" over the cover, it didn't take much force to slide it off one end or the other, at which point it would fall off and start dragging along the track. It only took four revisions to arrive at the final design. But that's beauty of 3D printing. The next revision is just a few hours away.

The next gen battery box is modelled to "mimic" the original 9V one. It is a complete box that snaps in place beneath the car. It has a sliding cover that snaps in place, like the original, to keep everything in place. The charging and programming access remains the same. The major difference is separate "ears" that are glued to the box to allow it snap in. The lid still slides in, but now a confident snap holds it in place.

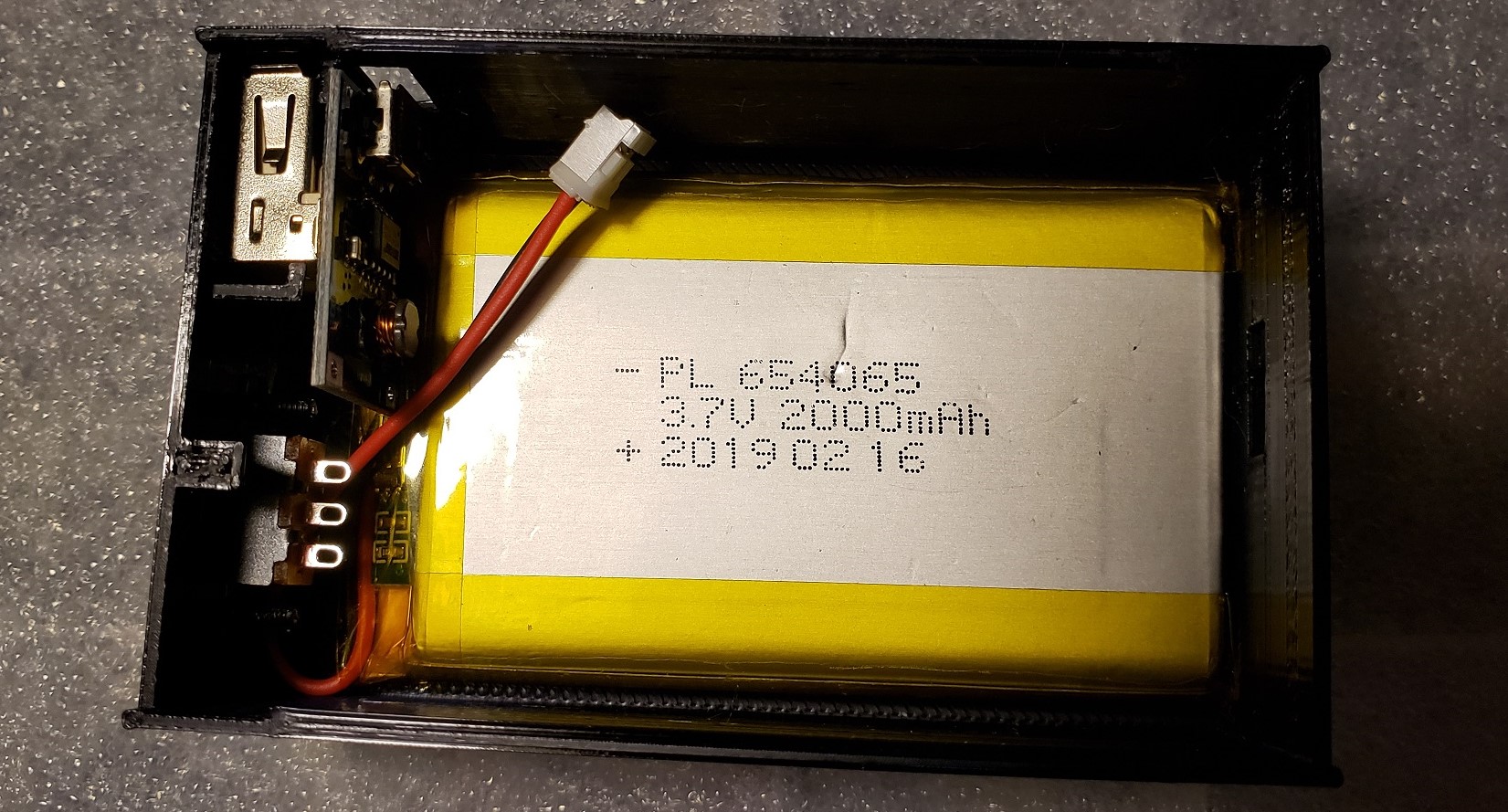

The biggest reason for the increased size of the battery box was the size of the 2000mAh LiPo battery. I already had a supply of them in stock and began developing gadgets for the Barkyard based around them. Another reason is the size of the arduino itself. There just isn't enough "real estate" inside that original 9V box to fit everything. So now I have an entire storage drawer full of original 9V battery boxes and a fleet of passenger cars with the "next generation" version attached.

So one day I was looking at that entire storage drawer full of original 9V battery boxes and started to wonder if I could find a LiPo battery that would fit inside it.

I already found a smaller form factor arduino, now if I could find a battery that would fit, maybe I could just use the original 9V battery box. I fiddled around with it

enough to actually get it to work! What's left of the battery box by the time I'm done is a good indication I should leave well enough alone...

See More...

We invite you to enjoy our Passenger Car Lighting series on the Barkyard YouTube channel if you're so inclined. We go into much more detail than we could possibly fit on a

web page. Even our Barkyard Blog posts can't capture all the details the videos can.

View Now...